Tokyo, Japan—Ricoh Company, Ltd. has developed an innovative 3D inkjet printing technology that enables the creation of full-color resin components with both high mechanical strength and biocompatibility. This breakthrough is expected to support the production of custom-made, design-sensitive parts, particularly in fields such as dentistry and eyewear.

1. Background

Custom-made products—such as dental prosthetics and eyeglass frames—require high quality and aesthetic detail. However, traditional manufacturing often depends on manual labor, making it time-consuming and costly. 3D printing has emerged as a potential solution, but existing technologies have limitations.

Previously, stereolithography-based 3D printing has been used to create items like dentures and eyeglass frames. While these methods can produce intricate shapes, they generally lack mechanical strength and only allow single-color output—falling short of aesthetic and durability expectations.

Denture fabricated by Ricoh technology

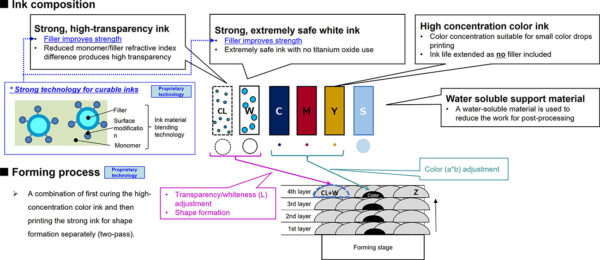

Material jetting, which uses inkjet technology and UV-curable resin, offers vibrant full-color output and is widely used for design prototypes. However, due to limited strength, it has not been suitable for functional parts. Ricoh has addressed this issue by developing a proprietary ink and process that together enable strong, precise, and full-color output.

2. Technology Overview and Results

Ricoh’s material jetting system incorporates a specially developed ink containing fillers that significantly boost mechanical strength while still being jettable. High-strength clear and white inks form the base, while highly concentrated yellow, magenta, and cyan inks are applied precisely to achieve full-color expression.

By optimizing the formulation of monomers and resins, the output is also biologically safe, passing JIS T 10993-1 testing standards for medical devices. This makes the technology suitable for clinical applications such as long-term dental prosthetics.

3. Future Potential

This technology has already been adopted by Core Dental Lab Yokohama and is being evaluated for clinical use. With strength superior to other dental 3D printers and the ability to replicate tooth color gradients, it allows not just temporary prosthetics but also long-term restorations, including premolars.

It also enables single-process printing of dentures combining teeth and gum areas, delivering clean, natural transitions between materials—ideal for high-aesthetic requirements.

Ricoh’s technology offers a unique combination of strength, aesthetics, and biocompatibility, opening doors for widespread use in both industrial and medical applications. Potential uses include eyeglass frames and epitheses—custom prosthetic parts replacing body elements lost to injury, illness, or congenital conditions.

Ricoh continues to refine this platform and explore expansion into international markets including Europe and North America.