Solimar Systems, Inc., a leading workflow automation solutions provider, announces remarkable results from its long-standing partnership with Johnson & Quin, a pioneering direct mail production company. By implementing Solimar’s Chemistry™ platform, Johnson & Quin has dramatically reduced processing times, optimized quality control, and achieved significant cost savings.

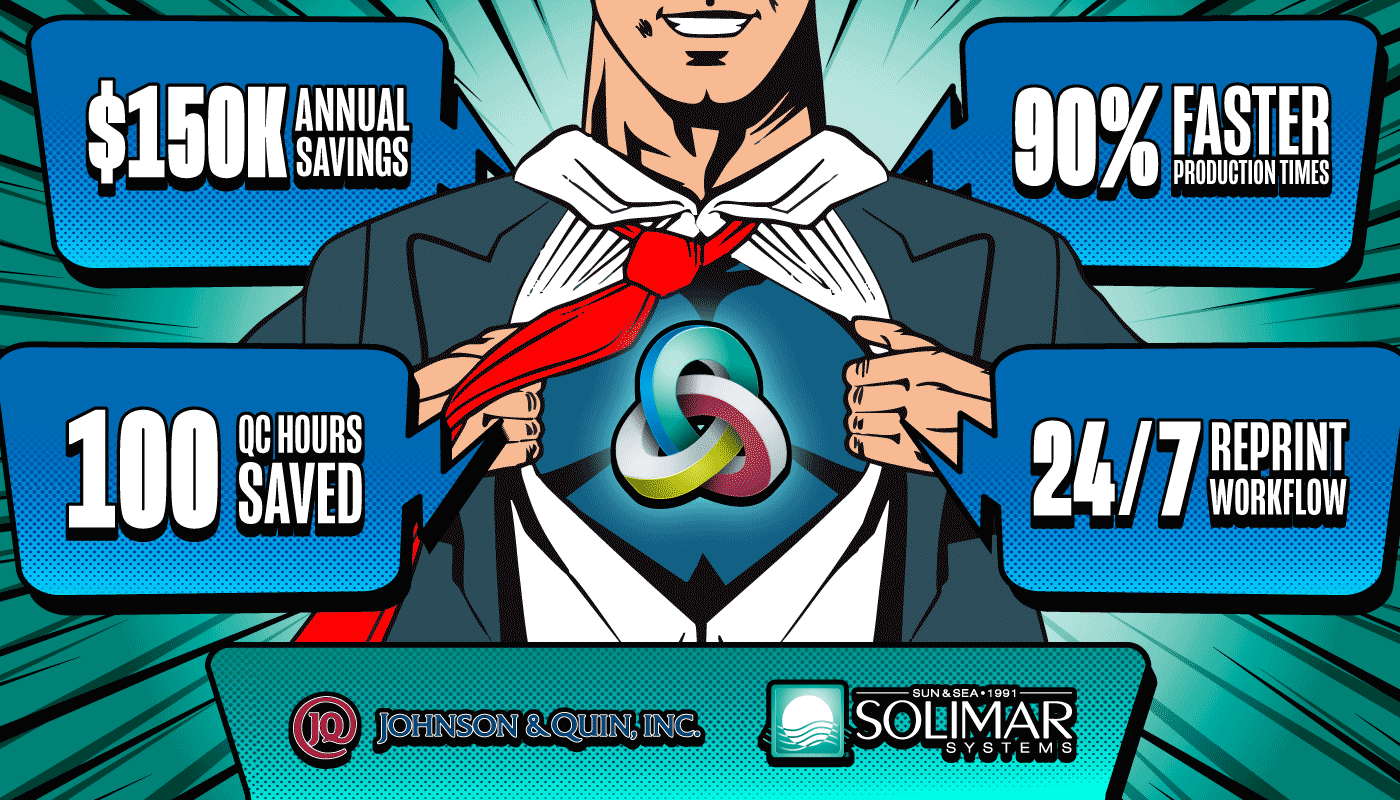

“The newest advancements have allowed us to reduce the time from approval to production by up to 90% versus the previous workflow,” states Manish Haria, CISO and CIO at Johnson & Quin. This transformation has been particularly evident in their daily operations, where the company now saves up to four hours of processing time on larger print jobs.

Key achievements include:

- Streamlined 100 labor hours in the quality control process

- Enhanced 24/7 reprint capabilities

- Annual savings exceeding $150,000

- Improved flexibility in meeting SLAs and postal deadlines

- Increased data integrity and processing efficiency

The success story began with the implementation of Solimar® Print Director™ and expanded with the addition of Rubika®, particularly its innovative De-imposition Module. These solutions have enabled Johnson & Quin, founded in 1876, to maintain its position as an industry leader while adapting to modern direct mail production demands.

“With the De-imposition module, we are saving up to 4 hours each day of processing time previously needed on our large jobs, which gives us more flexibility in production to meet difficult SLAs and postal cutoffs,” explains Nicholas LaCapra, IT manager at Johnson & Quin.

“We are grateful to have Manish as an active Solimar Customer Advisory Council member,” states Mary Ann Rowan, Solimar CXO. Johnson & Quin has been a Solimar customer for over two decades, providing us with valuable insights and enhancement requests. We are thrilled to be an integral provider driving operational excellence, giving Johnson & Quin a competitive edge in the direct mail services industry.”